Gift Cards

Scalable Gift Card Production for High-Volume Retail.

High-volume gift and loyalty cards for retail and gift card providers.

We support retailers and gift card companies with reliable production, flexible capacity and modern eco materials – managed from the UK, manufactured at scale.

- High-volume capacity from our ISO-certified 2,500 m² facility (up to 10–15M cards/month).

- UK-based account management, contracts and VAT invoicing.

- Eco materials and premium finishes for modern gift card ranges.

Built for the Complexities of Gift Programmes

Peak Season Assurance

Guaranteed capacity allocation for Q4 peaks. Split-delivery options to manage your warehouse flow.

Zero-Error Data

100% camera-verified matching for PINs and barcodes. We treat activation data with banking-grade security.

Brand Consistency

Strict colour management across PVC, Paper and Wood – so your brand looks the same on every card and carrier.

Local Accountability

UK-based account management, contracts and VAT invoicing – easy communication across teams, time zones and audits.

Unconstrained Design & Technical Precision

Personalisation as an Art. From complex foils to secure data encoding. We execute your specification to the letter.

Card bodies & materials

PVC, recycled PVC / eco PVC, paper and wood cards, 0.5–0.76 mm, custom sizes.

Print & finishes

Heidelberg offset and HP digital, with matte, gloss, spot UV, metallic, mirror, glitering, 3D UV and foil options.

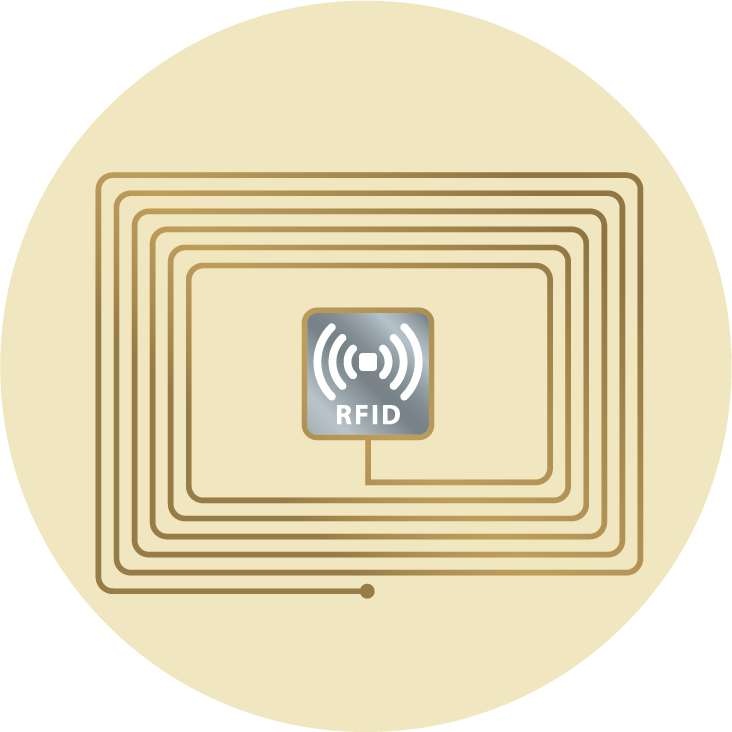

Security & features

Scratch-off PIN panels, holograms, security printing and optional RFID / NFC chips for enhanced protection.

Data & encoding

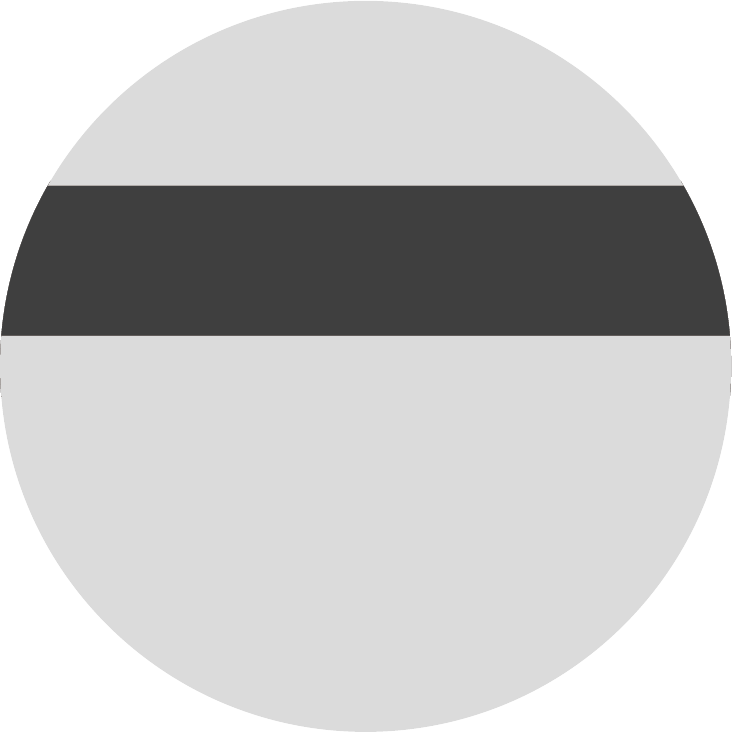

variable serial numbers, PINs, barcodes and QR codes across multiple designs and denominations, with secure magstripe / chip encoding and controlled data workflows.

Card Materials

- PVC

- Recycled PVC / Eco materials

- FSC-compliant paper card

- Wood veneer

- PET / PETG

Finishes

Gloss

Matt

Metallic

Mirror

Glitering

Pantone Color

3D UV Print

Clamshell

Core Features of Our Gift Cards

Scratch-off Panels

Ideal for PIN codes, activation numbers, voucher codes or secure verification. Available in silver, gold, transparent or custom colours.

Barcode & QR Code Printing

Supports all major standards including UPC, EAN, Code 39, Code 128 and custom QR codes. Perfect for POS scanning, e-commerce redemption or loyalty systems.

Variable Data & Encoding

We support complete in-house encoding services: Magnetic stripe encoding All data is processed securely under strict production control.

Full Range of Personalisation

Barcodes

QR Codes

Embossing

Spot UV

Die-Cutting/Custom Size

NFC/RFID

Scratch Panel

Magnetic Stripe

Sigunature Panel

Holograms

Protecting Film

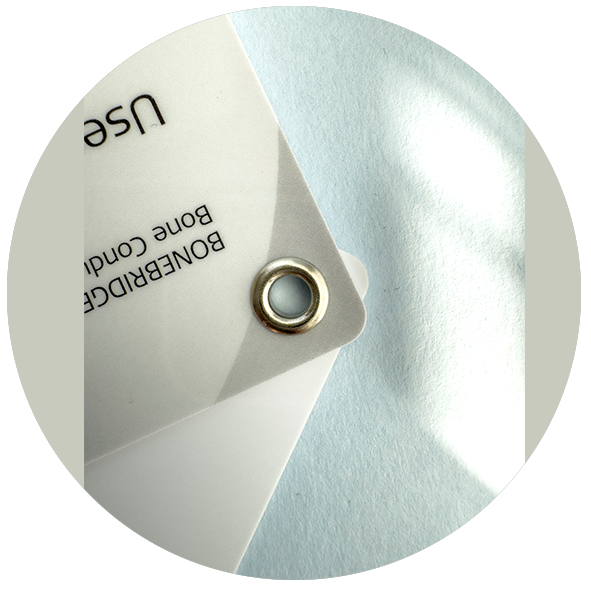

Metal Eyelet

Stripe Punch

Silver/Gold Foil

Poly Bag/Card holder

Card carriers, sleeves and retail packaging

Gift cards rarely travel alone. We design and produce carriers, sleeves, hangers and gift packs that fit your fixtures, stock flow and customer experience – so the card, packaging and in-store display all work as one.

Retail-ready formats

Folded carriers, hangers, sleeves and multipacks engineered to work with your existing hooks, pegs and fixtures in-store.

Materials and sustainability

Choice of coated boards, kraft and speciality papers, with recycled and FSC-compliant options available to support your ESG targets.

Brand-consistent design

We align carrier and packaging artwork with your gift cards – matching colours, finishes and messaging across the whole range.

Kitting and packing options

Cards can be kitted into carriers, banded, poly-bagged or boxed to your specification, with clear carton labelling to match your warehouse and rollout plan.

How we fit into your gift card programme

Innovation for your next range

We collaborate with your team to develop new gift card formats, materials and finishes – from eco ranges to premium limited editions – and turn ideas into production-ready cards.

Built for established programmes

We plug into existing gift card programmes – adding production capacity, supporting specific campaigns or handling selected SKUs under your current structure.

Flexible roles, front or back

We’re used to working alongside retailers, gift card providers and manufacturers. Some clients ask us to produce under their own brand, others introduce us by name – we’re comfortable either way.

Selected Gallery

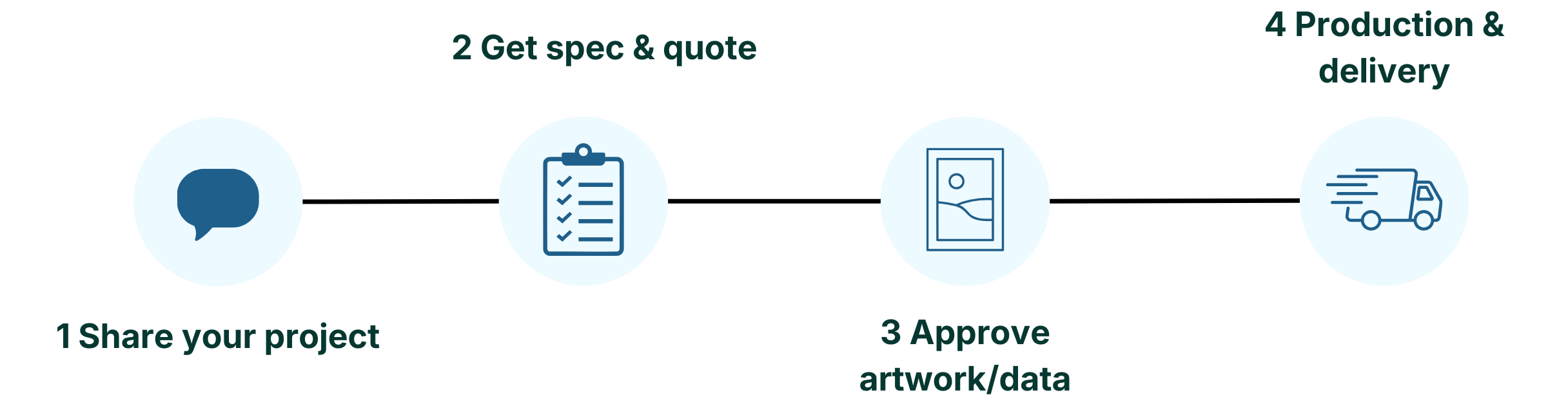

1. Share your project

Tell us what you need for this product – quantity, rough timing and how the cards/tags will be used.

You can send a photo of an existing card, a sketch or a simple description.

If you already have a full spec, that’s great. If not, we’ll help you define it.

2. We confirm spec & quote

We review your brief and suggest suitable materials, chips/magstripes and finishes for this application.

You’ll receive a clear, itemised quotation with lead time and options.

No obligation at this stage – you can adjust anything before going ahead.

3. Artwork / data approval

Upload your artwork files or let us tidy / set them up to print.

We send an e-proof (and physical sample if required for larger or repeat trade jobs) for your approval.

At this step we also confirm any encoding or personalisation details.

4. Production & delivery

Once you approve the proof and send PO/payment, we schedule production.

Our team keeps you updated and arranges shipping to one or multiple delivery points.

Re-orders are even simpler – we just reconfirm quantities, dates and any small changes.

4-step Order Process

You don’t need perfect artwork or detailed specs to start.

Just tell us what you’re trying to do – we’ll handle the technical side

Get Your Personalised Quote

Whether you have final artwork or just a rough concept, we’re happy to help.

Upload your files or leave us a note, and our UK team will prepare accurate pricing based on your card type, materials, and finishes.

Factory-direct production, fast local support.